Better for you, your customers and the environment

Safety and peace of mind

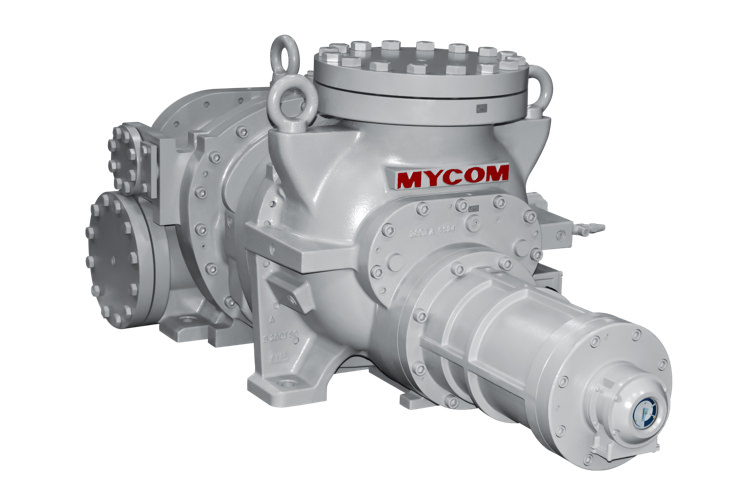

MYCOM compressors meet international standards

MYCOM compressors meet international standards

Sustainable society

Environmental conservation and resource validation through gas recovery technology

Environmental conservation and resource validation through gas recovery technology

Improved productivity

Development capabilities allow us to satisfy high productivity and safety demands

Development capabilities allow us to satisfy high productivity and safety demands

MYCOM supports production sites, including offshore development

At production sites related to oil, gas, and especially offshore development, accidents can lead to significant damage and serious environmental problems. MYCOM screw compressors have a proven track record of use on oil carriers and offshore platforms since the 1980s, and are compatible with international standards such as API, and ship classifications standards such as ABS and DNV. Responding to rigorous production site demands, compressors and cooling systems based on the MYCOM compressor have been positively recognized at various sites around the globe for supporting safe operations.

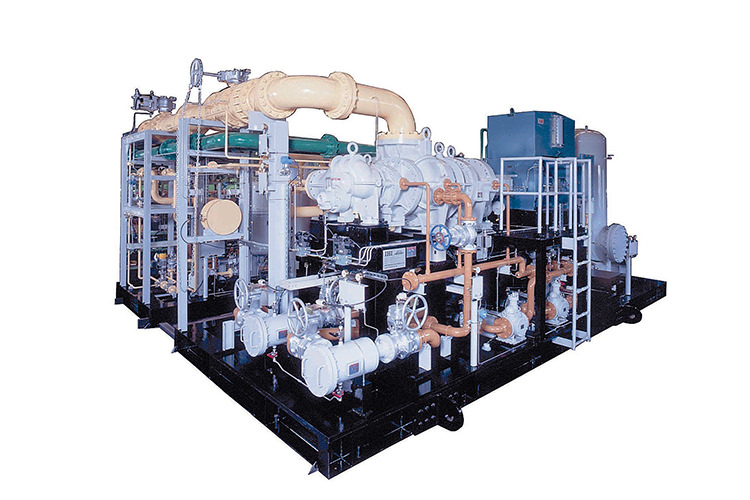

Supporting a sustainable society through environmental conservation and effective resource recovery

Always aiming for sustainability, oil and gas production sites are promoting the recovery and reuse of exhaust gas that has been incinerated in flare stacks in order to curtail CO2 emissions.

Additionally, volatile organic compounds (VOC) occurring in crude oil storage tanks and oil carrier are odorous and contain harmful substances such as benzene, so reducing their release into the atmosphere is high priority. These gases are mixed gases of varying compositions that include condensates (including highly corrosive hydrogen sulfide contained in associated gas) and are thus difficult to compress. However, with Mayekawa's unique compression and lube oil system, stable operations can be relied upon.

Contributing to environmental conservation and effective resource recovery, MYCOM compressors are used at sites around the world as recovery compressors and as refrigeration systems for gas processing.

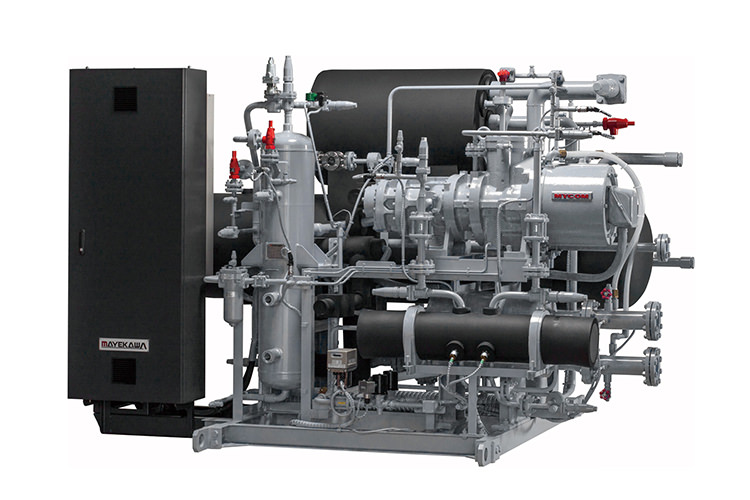

Adaptable for use in various applications

The oil and gas industry plays a primary role in supplying many industries with energy and basic raw materials for industrial products. Naturally, high durability, reliability, and high technical specifications are required by these production facilities.

Mayekawa's compressor technology makes it possible to compress natural gas that contains large amounts of condensates and corrosive components something that has conventionally been difficult to do. Additionally, our technology is suitable not only for general purpose applications such as brine and water chillers but for special cooling systems as well, including direct expansion liquefaction and cooling systems of process fluids for energy conservation, boil-off gas (BOG) reliquefaction systems for liquified gas, and cooling systems requiring temperatures of around minus-100°C. In consideration of global warming, we are promoting the adoption of natural refrigerants, including CO2, hydrocarbons ammonia and propane.

Based on our high-level technical capabilities, we can individually design and manufacture systems for various applications, and our design flexibly helps us offer proposals in line with client needs, from improving process reliability and safety to reducing overall operating costs.

BOG System