MYCOM SCADA is a supervisory control system specifically designed to monitor and manage MYCOM (Mayekawa) refrigeration and compressor systems. It is not a general-purpose SCADA platform, but one customized or optimized for MYCOM industrial machines, often used in refrigeration-heavy industries like food processing and cold storage.

Main Components of MYCOM SCADA System

1. Field Devices (Sensors/Actuators):

- Temperature sensors

- Pressure sensors

- Valves

- Motorized valves

- Gas detectors

- Level sensors

- Float switch

2. Programmable Logic Controllers (PLCs):

- These collect data from the field devices and execute control commands.

- They communicate with the SCADA software.

- We use brands like - SIEMENS, MITSUBISHI AND ALLEN BRADLLEY, but we can be flexible to customer's brand preference.

3. SCADA Software Interface:

- This is where operators see dashboards, system graphics, alarms, trends, and logs.

- MYCOM typically integrates its own logic, compressor data, and parameters here.

4. Human-Machine Interface (HMI):

- Provides real-time interaction with equipment (e.g., start/stop compressors, set points).

5. Communication Network:

- Connects compressors, sensors, PLCs, and the SCADA system (often using industrial protocols like Modbus, Ethernet/IP, Profibus, Profinet, Modbus TCP, OPC UA, DeviceNet, HART, CC-Link).

Key Functionalities of MYCOM SCADA

| FUNCTION | DESCRIPITON |

|---|---|

| Real-Time Monitoring | Live display of compressor pressures, temperatures, oil levels, and runtime hours. Real-Time Monitoring Cold storage - fan status, valve status, temperature. Vessel - level, temperature, valve status, ammonia pump status. |

| Alarm & Fault Management | Triggers alerts for abnormal conditions such as high discharge pressure or oil level failure. High or low temperature alarms. Motor trip. Early warning for alarm. |

| Data Logging / Trends | Historical data trends for analysis and troubleshooting (e.g., temperature over time). |

| Compressor Control Energy | Start/stop compressor units, switch from automatic to manual, change setpoints. |

| Monitoring / Energy Efficiency | Track power consumption, system load, and operational efficiency. |

| Safety Interlocks | Built-in protection to prevent compressor damage (e.g., shutdown on overheat). High level on vessel interlock. Defrost interlock on cold storage. |

| Remote Access (optional) | Some versions support remote desktop or web-based access for off-site monitoring. We can offer WinCC Unified or IGNITION for remote version. |

Where You Commonly See MYCOM SCADA

- Ice plants controlling multiple MYCOM ammonia compressors

- Cold storage warehouses ensuring stable temperatures 24/7

- Food processing facilities that rely on consistent cooling for meat, dairy, or seafood

- Beverages & Brewery

Benefits of MYCOM SCADA

- Preventative Maintenance - Use runtime and alarm data to service machines before failures occur.

- Efficiency Optimization - Reduce power usage by adjusting operations based on load conditions.

- Operator Safety - Minimize manual interaction with high-risk machines (e.g., ammonia compressors).

- Faster Troubleshooting - Logs and trends make it easier to identify root causes of issues.

- Comprehensive Overview - One centralized screen for all critical compressor and refrigeration operations.

- Enhanced security - manages security level (e.g., visitor - level 1, operator - level 2, admin - level 3)

- Long term investment - it will probably cost more initially but will ensure future cost efficiency

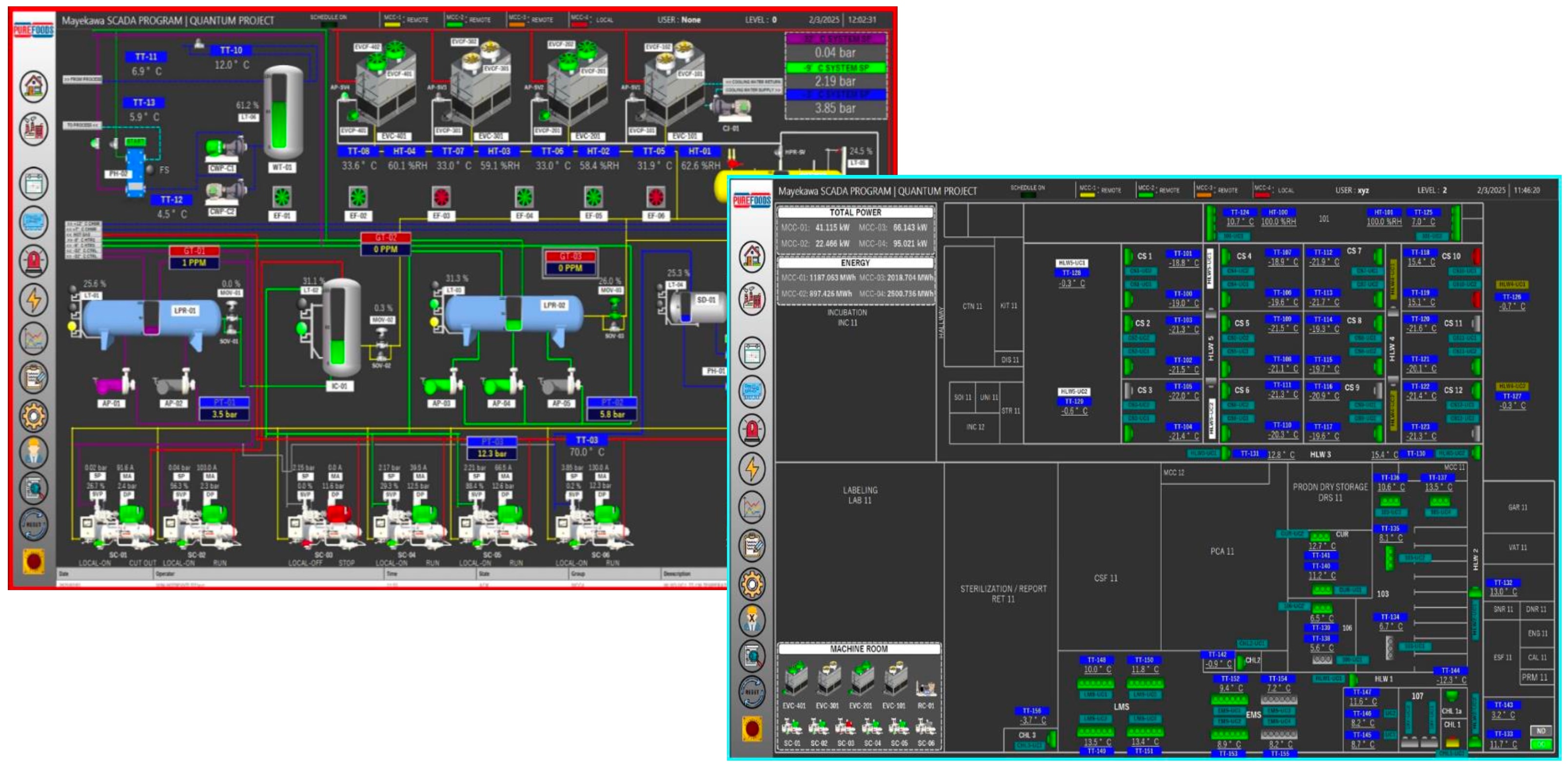

Example Interface (What You Might See)

- A screen showing a system flow diagram with all compressors, evaporators, condensers, etc.

- Color-coded readings:

- Green: Normal

- Yellow: Warning

- Red: Fault/Alarm

- Graphs showing:

- Suction and discharge pressures

- Motor current

- Compressor oil temperature

- Cold storage temperatures

- Energy consumption

- Energy efficiency

- Buttons:

- Start/Stop Compressor

- Acknowledge Alarm

- Switch Control Mode (Auto/Manual)

Conclusion

MYCOM SCADA is essential for automating and optimizing refrigeration systems using MYCOM compressors. It removes the guesswork and manual checks by giving you real-time visibility, control, and historical analysis, ensuring operations stay smooth and safe.Contact Mayekawa Today!

Achieve sustainable growth of your business.

Join the hundreds of Philippine businesses with Mayekawa MYCOM products!

Visayas (Cebu)

Unit D, A & J Building 6014

A. C. Cortes Ave

Alang-Alang Mandaue City, Cebu

Tel: +63 32-436-4885

Fax: +63 32-436-4885

Email: inquire@mayekawaphil.com

Luzon (Manila)

Unit 604, West Wing

Estancia Offices Meralco Ave.

Capitol Commons

Pasig, 1605 Metro Manila

Tel: +63 2-8706-0473

Fax: +63 2-8706-0475

Email: inquire@mayekawaphil.com

Mindanao (General Santos)

2F EJ Yomon Building

Irineo Santiago Boulevard Brgy

General Santos City

9500 South Cotabato

Tel: +63 2870-60473

Fax: +63 2870-60473

Email: inquire@mayekawaphil.com

Stay Connected

Facebook

Facebook

© 2022 Mayekawa Philippines Corporation

Mayekawa Philippines Corporation