SUPPORT

With Mayekawa, your business never stopsMaintenance

Accurate maintenance and quick responseWe will do our utmost to ensure your production line keeps running. To ensure the stable operation of your plant every day, we check the operating status of equipment and facilities from various perspectives such as vibration, thermographic analysis, and oil analysis, and formulate a plan for repairs and replacing parts tailored to your needs. Scheduled maintenance allows you to keep down costs by avoiding unexpected failures, and enables your facilities to operate in a manner that is long-lasting, efficient, and functional. In the event an unexpected failure or malfunction occurs, our service technicians on standby around the world can and will respond promptly to minimize downtime and help ensure a speedy return to production, we will investigate the root cause of any problems, and discuss improvements with you.

An overhaul to meet your needs

Whether you want to overhaul equipment on-site to ensure your production line is not interrupted, or make focused repairs at a Mayekawa workshop, our experienced staff are ready to answer the call. Aging equipment can even be upgraded with our latest designs through retrofit service work.

Predictive maintenance

Monitoring the operational trends and performance of facilities and equipment not only allows for more effectively scheduled maintenance, but also leads to the early detection of abnormal data and the prevention of any trouble before it occurs. We can develop and provide monitoring programs tailored to your needs.

Commissioning

In order to operate advanced machinery and equipment safely and efficiently, sophisticated adjustments for each piece of equipment are critical. Highly skilled and experienced commissioning technicians are ready to help you make optimal adjustments to your facilities so that any new facilities will run smoothly and operate at peak performance.

Training & Lecture

Our experienced technicians can offer training at participating locations. We have programs available to suit your needs, such as lectures to learn basic theories like freezing cycles and coolant characteristics, how a MYCOM compressor works and its components, as well as practical lectures for trial operation and overhauls. Please inquire about available training at your nearest Mayekawa branch.

Technical support

Your facilities and plants are required to keep up and comply with new safety, environmental, and quality standards as they are updated around the world. We support equipment and plant renewal and optimization efforts with an emphasis on important charactiersitics like performance, efficiency, and safety by using our in-depth knowledge of refrigeration systems, compressors, and electrical systems to ensure that your facilities and plants always operate at their best. We share any issues with you and make proposals for improvements so that existing facilities and plants can be upgraded to meet your needs with minimal investment and a short construction period. What's more, based on the information obtained from daily maintenance, predictive maintenance, and our monitoring systems, we enable facilities and plants to deliver their full potential by examining efficient operation methods with you as well as assisting in initiatives to reduce energy consumption and improve production efficiency.

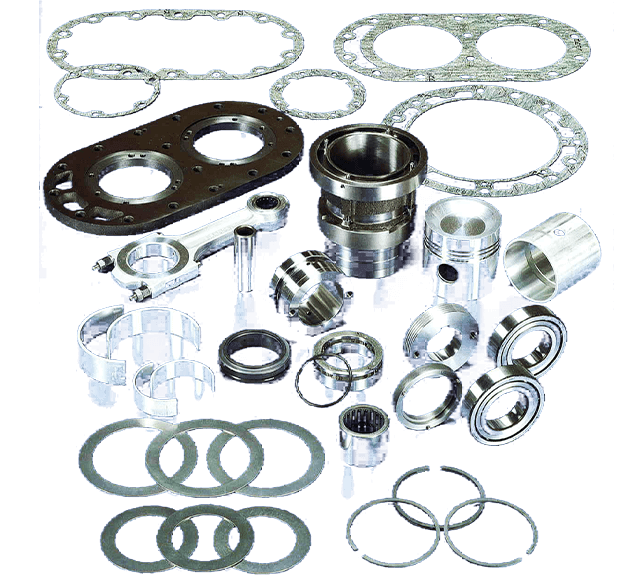

Spare parts

It is essential to use genuine spare parts in order for your facilities and plants to continue to operate stably and with an appropriate service life. Through our global service network, we have a system in place to deliver parts quickly. Contact your nearest Mayekawa branch should you have any questions. *Refer to the Compressor Parts page for details.

Contact Mayekawa Today!

Achieve sustainable growth of your business.

Join the hundreds of Philippine businesses with Mayekawa MYCOM products!

Visayas (Cebu)

Unit D, A & J Building 6014

A. C. Cortes Ave

Alang-Alang Mandaue City, Cebu

Tel: +63 32-436-4885

Fax: +63 32-436-4885

Email: inquire@mayekawaphil.com

Luzon (Manila)

Unit 604, West Wing

Estancia Offices Meralco Ave.

Capitol Commons

Pasig, 1605 Metro Manila

Tel: +63 2-8706-0473

Fax: +63 2-8706-0475

Email: inquire@mayekawaphil.com

Mindanao (General Santos)

2F EJ Yomon Building

Irineo Santiago Boulevard Brgy

General Santos City

9500 South Cotabato

Tel: +63 2870-60473

Fax: +63 2870-60473

Email: inquire@mayekawaphil.com

Stay Connected

Facebook

Facebook

© 2022 Mayekawa Philippines Corporation

Mayekawa Philippines Corporation