Cooling systems for industrial processes

Systems from Mayekawa are used for a wide range of applications, including cooling fuel oil used in various ships, HIgh energy physics and fusion science laboratories, and cooling processes in the petrochemistry and medical fields. With technical expertise developed over many years, we can propose and develop unique systems that meet highly challenging client needs, such as those related to specific temperature zones, including ultra-low and cryogenic.

Cryogenic

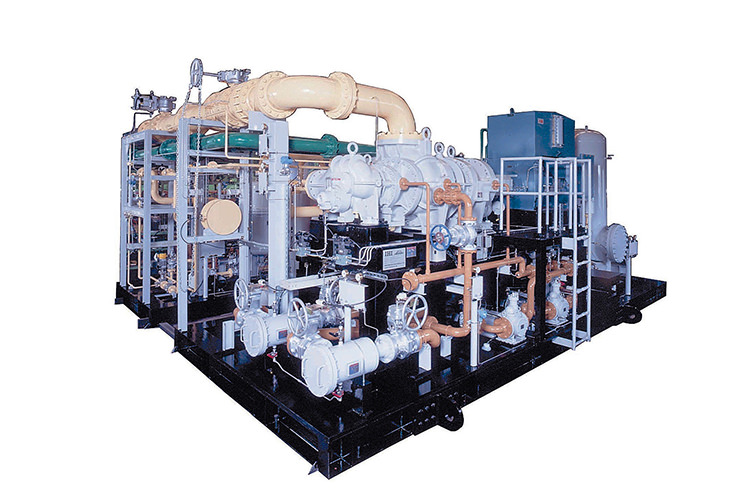

Helium gas compressor

Helium gas compressor

Helium gas compressor

We have been responding to client needs since developing the world's first oil-injection helium compressor

almost a half-century ago. We are rated highly on various aspects, such as our simple packages realized by

using Mayekawa's original large compound compressor and the adoption of new lubricants that suppress the

generation of impurities. We have an extensive and proven track record in HIgh energy physics and fusion

science laboratories, and are active all over the world, including Japan, the US, Germany, France, China,

Russia, India, and South Korea.

SPECIFICATIONS

WHERE TO USE

Cryogenic

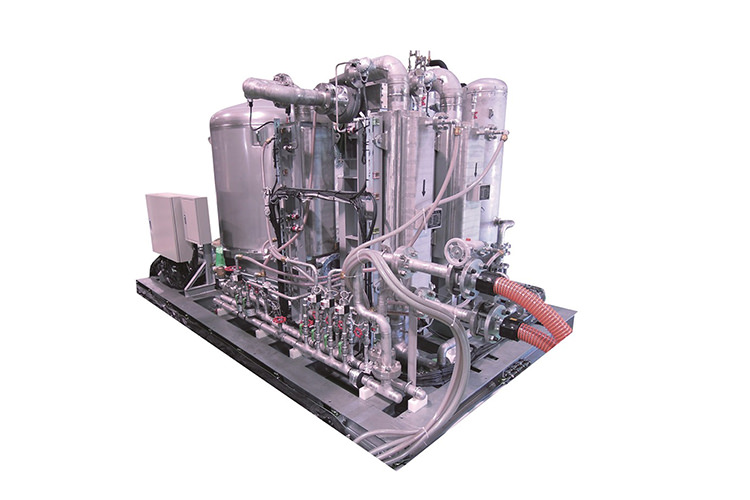

Brayton NeO - brayton cycle cryocooler

Brayton NeO

Brayton NeO

Brayton NeO is possible to cool below -220℃ (-364℉) utilizing a reverse Brayton cycle

and a turbo compressor and expander.

We have provided the cooling system for high-temperature superconducting (HTS) device, the liquefier of LNG and the alternative cooling system of liquid nitrogen.

This refrigerator is used in industrial and medical, food industrial fields.

We have provided the cooling system for high-temperature superconducting (HTS) device, the liquefier of LNG and the alternative cooling system of liquid nitrogen.

This refrigerator is used in industrial and medical, food industrial fields.

SPECIFICATIONS

* class at 77 degrees Kelvin

WHERE TO USE

Ultra-low temperatures

PascalAir Brine Cooler Unit - air cycle system -50 to -90℃ (-58 to -130℉)

PascalAir Brine Cooler Unit

PascalAir Brine Cooler Unit

PascalAir is an air cycle system that employs glycol as an air refrigerant and uses a heat exchanger to

create an ultra-low temperature range -50 to -90℃ (-58 to -130℉) with an air cycle.

Air, not HFCs, serves as the refrigerant, so the refrigerant does not negatively impact the environment. Furthermore, in the ultra-low temperature range -50 to -90℃ (-58 to -130℉), it is possible to reduce CO2 emissions and achieve energy savings of up to 50% over conventional vapor compression cooling systems.

Air, not HFCs, serves as the refrigerant, so the refrigerant does not negatively impact the environment. Furthermore, in the ultra-low temperature range -50 to -90℃ (-58 to -130℉), it is possible to reduce CO2 emissions and achieve energy savings of up to 50% over conventional vapor compression cooling systems.

SPECIFICATIONS

WHERE TO USE

BOG reliquefaction

BOG gas reliquefaction equipment

BOG gas reliquefaction equipment

BOG gas reliquefaction equipment

It is inevitable that liquefied gas storage tanks will have some of their content gasified due

to external heat inputs or cargo handling. Such gas is known as boil-off gas (BOG). Reliquefaction

equipment for BOG re-liquefies the BOG by compressing and condensing it and then returns it to the tank.

Mayekawa offers various gas re-liquefaction compressors and cooling systems for use in both onshore storage

and marine transport tankers.

SPECIFICATIONS

WHERE TO USE

MGO (Marine Gas Oil) cooling system

MGO cooling system

MGO cooling system

Compact and flexible designed fresh water chilling unit

Very easy and reliable operation

And with a combination of automatic controlled three way control valve installed on the outlet of MGO cooler, the MGO temperature to be finally controlled fully automatically and very accurately.

SPECIFICATIONS

Related Applications

Contact Mayekawa Today!

Achieve sustainable growth of your business.

Join the hundreds of Philippine businesses with Mayekawa MYCOM products!

Visayas (Cebu)

Unit D, A & J Building 6014

A. C. Cortes Ave

Alang-Alang Mandaue City, Cebu

Tel: +63 32-436-4885

Fax: +63 32-436-4885

Email: inquire@mayekawaphil.com

Luzon (Manila)

Unit 604, West Wing

Estancia Offices Meralco Ave.

Capitol Commons

Pasig, 1605 Metro Manila

Tel: +63 2-8706-0473

Fax: +63 2-8706-0475

Email: inquire@mayekawaphil.com

Mindanao (General Santos)

2F EJ Yomon Building

Irineo Santiago Boulevard Brgy

General Santos City

9500 South Cotabato

Tel: +63 2870-60473

Fax: +63 2870-60473

Email: inquire@mayekawaphil.com

Stay Connected

Facebook

Facebook

© 2022 Mayekawa Philippines Corporation

Mayekawa Philippines Corporation