Freezers

Our mission is not simply to freeze food products.We aim to provide the ultimate way to efficiently maintain quality, providing optimal freezer solutions for a wide variety of products including seafoods, agricultural products, livestock products, sweets, breads, and prepared foods of varying shapes, sizes, and thicknesses.

We also share values cherished by our customers, working closely with customers at all times to provide solutions tailored to the needs and challenges unique to each country and area.

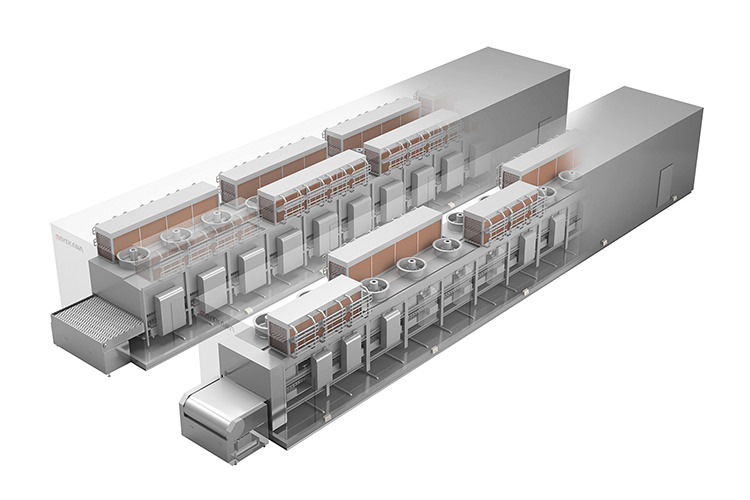

Tunnel type

Thermo-Jack Freezer - continuous rapid freeze apparatus

Thermo-Jack Freezer

Thermo-Jack Freezer

Ideal freezing (or chilling) for all kinds of products.

Impinging jets are used in addition to the conventional air blast freezing system for a straight

continuous tunnel freezing system that reduces freezing (or chilling) time from 1/2 to 2/3 of the

conventional time.

This multi-purpose freezer has two types of conveyor belts - a mesh belt and a solid steel belt - making it suitable for a wide variety of products from liquid or granular products to bagged or unwrapped products.

This multi-purpose freezer has two types of conveyor belts - a mesh belt and a solid steel belt - making it suitable for a wide variety of products from liquid or granular products to bagged or unwrapped products.

SPECIFICATIONS

Mesh type:

1,200 to 3,300mm (intervals of 300mm)

≒47.2 to 129.9in (intervals of 11.8in)

Steal type:

1,200 or 1,500mm

≒47.2 or 59.1in

3,000 to 21,000mm(intervals of 1,500mm)

≒118.1 to 826.8in(intervals of 59.1in)

Frozen & Chilled

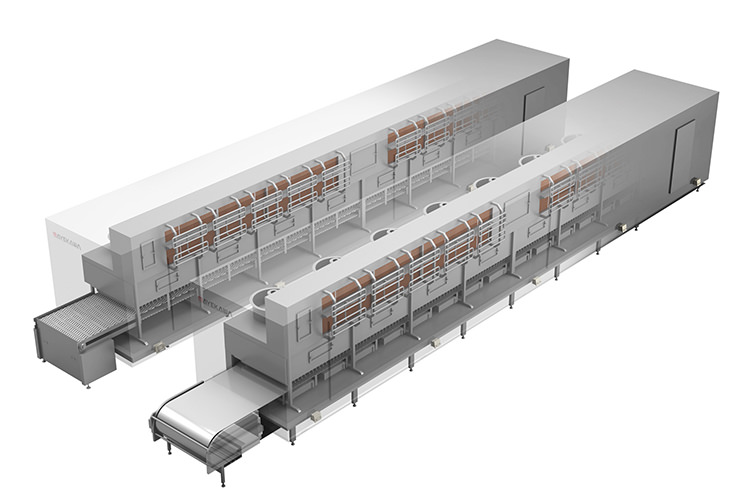

Thermo-Jack Rey - continuous rapid freeze & chill apparatus

Thermo-Jack Rey

Thermo-Jack Rey

A continuous rapid freezer and chiller which incorporates the technology and know-how that

Mayekawa has developed in the field of food processing.

The hygiene required in food processing factories has been improved and space-saving and uniform cooling qualities have also been realized.

The hygiene required in food processing factories has been improved and space-saving and uniform cooling qualities have also been realized.

SPECIFICATIONS

3,000 to 21,000mm(intervals of 1,500mm)

≒118.1 to 826.8in (intervals of 59.1in)

Tunnel type

SlimLight Freezer - continuous rapid freeze apparatus

SlimLight Freezer

SlimLight Freezer

Space-saving, produced integrally at our factory and transported in one shipment

All the necessary functions of the Thermo-Jack Freezer but even easier to use.

It is also produced integrally at our factory and transported in pieces, dramatically shortening installation time.

It is also produced integrally at our factory and transported in pieces, dramatically shortening installation time.

SPECIFICATIONS

3,000 to 18,000mm (intervals of 1,500mm)

≒118.1 to 708.7in(intervals of 59.1in)

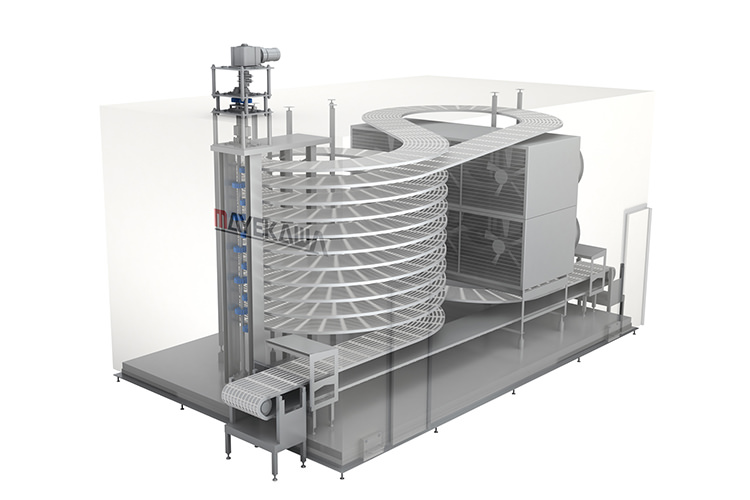

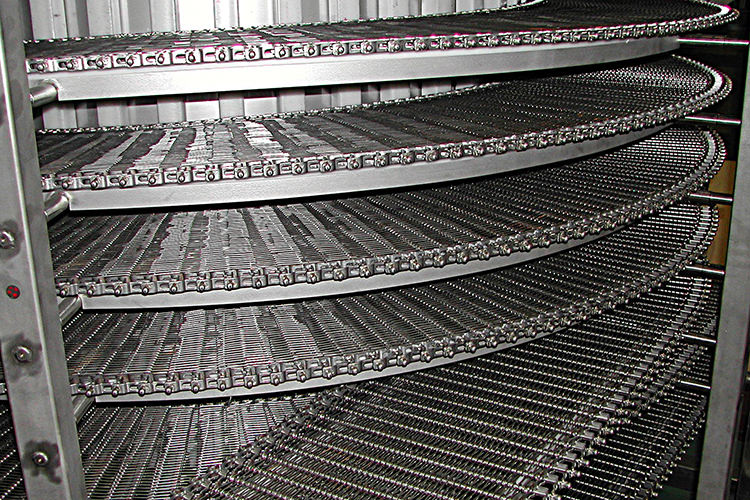

Spiral type

MultiLayered Freezer - continuous freeze apparatus

MultiLayered Freezer

MultiLayered Freezer

Bottom loading and unloading possible from single tower. Can be used for flexible layouts.

Instead of the drum main axis chain drive method used in conventional spiral freezers, this freezer uses

a peripheral sprocket system for a simpler structure that is easier to clean. The internal diameter is also

smaller than in conventional freezers, allowing a layout that fits in a compact space.

SPECIFICATIONS

(≒.7/25.6/29.5/33.5/37.4in)

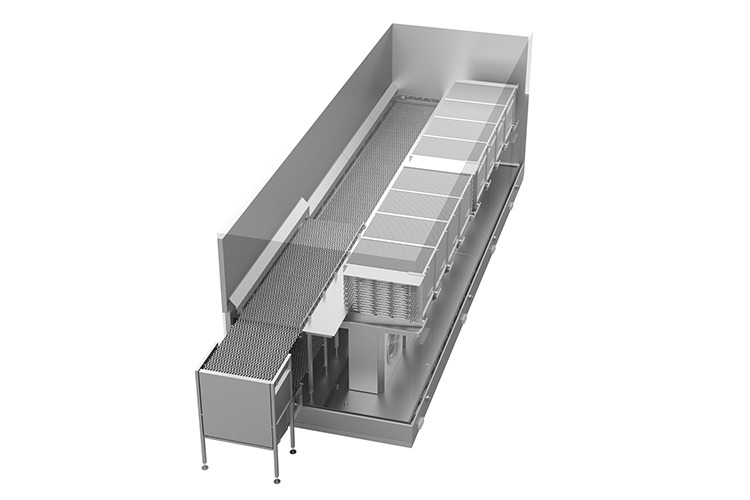

IQF

IQF Line Freezer - individual quick freeze apparatus

IQF Line Freezer

IQF Line Freezer

Ideal for freezing vegetables, fruit and fishery products without clumping

The product is scattered and surface frozen on the first conveyor and then fully

frozen in multiple layers on the second conveyor.

This multi-layered freezing allows a more compact installation space.

This multi-layered freezing allows a more compact installation space.

First conveyor

A strong upward air flow is applied from the bottom and vibration is applied from

below to scatter the product while freezing the surface of the product.

Second conveyor

The product is frozen all the way to the center. The product is stacked in multiple

layers, allowing a more compact freezer to be used.

SPECIFICATIONS

813mm (Effective width: 720mm)

≒32.0in (Effective width: 28.3in)

1524mm (Effective width: 1430)

≒60in (Effective width: 56.3in)

Spiral type

Spiral Freezer - continuous freeze apparatus

Spiral Freezer

Spiral Freezer

The conveyors are arranged three-dimensionally, allowing continuous freezing for mass production in a small installation space.

This type can be used for all kinds of products.

SPECIFICATIONS

500 to 900mm (increments of 50)

≒ 19.7 to 35.4in

Batch type

Batch Freezer - rapid freeze apparatus

Batch Freezer

Batch Freezer

It is suitable for a wide variety of products, with controllable time and air flow. A trolley conveyance type is

also available, allowing first-in-first-out production plans.

SPECIFICATIONS

Related Applications