Deboning machines

Mayekawa has been introducing robotic products that automates deboning process. It was a challenge to develop new technologies that let machines handle irregularly-shaped soft objects, which had never been done before.The journey to develop a fully automated deboning machine all began with "TORIDAS", the automated chicken whole leg deboning machine. Today, we offer a variety of automated deboning machines that meet high standards of quality and yield.

Poultry

TORIDAS - automated chicken whole leg deboning machine

TORIDAS

TORIDAS

In the past, deboning of the whole chicken legs was human-labour dependent. We are pleased to say

that Mayekawa was successful in automating this process. By simply loading the bone-in leg in it,

TORIDAS will separate the bone from the meat, while giving you yield as high as that of manual deboning.

Automating the deboning process will provide stability in the quality and yield, all the while satisfying

the hygienic requirement.

Output

Output

Thigh meat & drum stick *Options

Thigh meat & drum stick *Options

SPECIFICATIONS

WHERE TO USE

Poultry

LEGDAS - automated chicken whole leg deboning machine

LEGDAS

LEGDAS

LEGDAS has achieved triple the processing speed with yield close to that of TORIDAS of which more

than 1,500 units have been installed in 26 countries around the world so far. By simply loading the

-in leg in it, LEGDAS will separate the bone from the meat, while giving you yield as high as that

of manual deboning. Automating the deboning process will provide stability in the quality and yield,

all the while satisfying the hygienic requirement.

Output

Output

Thigh meat & drum stick *Options

Thigh meat & drum stick *Options

SPECIFICATIONS

3,000 left legs

3,000 right legs

1,500 for left legs + 1,500 for right legs

WHERE TO USE

Poultry

YIELDAS 3000-E1 - automated front half deboning machine

YIELDAS 3000-E1

YIELDAS 3000-E1

The image processing feature allows cutting for all meat that is shaped differently. By automating the segmentation

of breast meats, YIELDAS 3000-E1 can produce, fillets wings, tenders as well as carcasses with a simple load of front halves.

Output

Output

SPECIFICATIONS

*Front half with broken carcass and/or hip carcass cannot be processed.

WHERE TO USE

Poultry

WINGDAS - automated chicken wing drumettes deboning machine

WINGDAS

WINGDAS

The manual deboning process was very difficult for chicken wing drumettes prior to this new development.

Deboning chicken wing drumettes through the WINGDAS is done by our automation process. Either deboned chicken

wing drumettes or deboned chicken tulips, also known as chicken lollipop wings can be produced. The appearance

of meat has high quality, high yield and it is reliable. It is capable of a full wash down to prevent cross contamination.

Boneless chicken drumettes (after trimming)

Boneless chicken drumettes (after trimming)

Chicken tulip/lollipop wings (after trimming)

Chicken tulip/lollipop wings (after trimming)

SPECIFICATIONS

WHERE TO USE

Poultry

TAKIDAS - automated turkey whole leg deboning machine

TAKIDAS

TAKIDAS

Automated slitting and final separation feature are the standard features. TAKIDAS automates the deboning

process of bone-in leg meat and separates the bone and leg meat after the turkey whole leg is loaded on the machine.

Output

Output

SPECIFICATIONS

WHERE TO USE

Meat

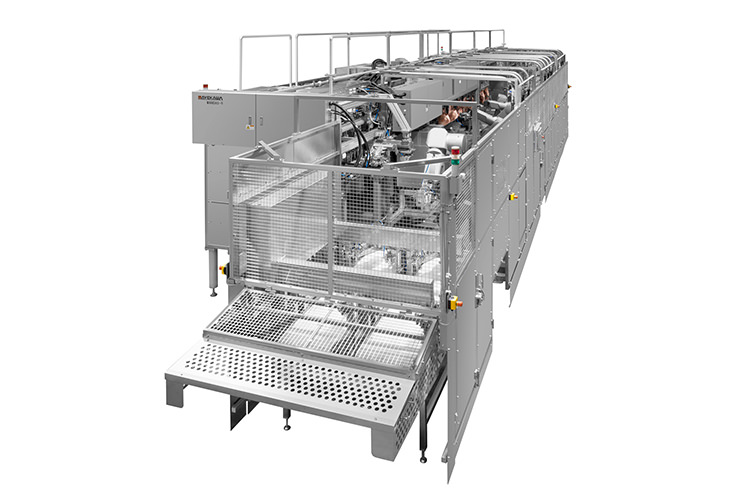

HAMDAS-RX - automated pork ham deboning machine

HAMDAS-RX

HAMDAS-RX

Mayekawa has developed the world's first automated ham deboning robotic machine. HAMDAS-RX automatically

debones pork ham after pre-cutting is performed. The auto measuring feature allows precision cuts to the

correct specifications of each ham and provides optimal yield.

Output

Output

SPECIFICATIONS

*Both hipbone and tailbone must be removed prior to deboning.

WHERE TO USE

Meat

WANDAS - RX-automated pork shoulder deboning machine

WANDAS-RX

WANDAS-RX

Mayekawa has developed an automated pork shoulder deboning robotic machine, the WANDAS-RX. It utilizes the

technology of the HAMDAS-RX. Our image processing and auto measuring features with a vertical multi jointed

robotic arm allows WANDAS-RX to process precision cuts on various sized pork shoulders.

Output

Output

SPECIFICATIONS

WHERE TO USE